Bill of material (BOM) Apps - Tool risk analysis

Problem definition:

Assembly devices, injection molding and stamping & bending tools are an essential part of the production infrastructure. If such a tool breaks down due to suddenly necessary major repairs, the production comes to a standstill. In most cases, a large number of other items (different colors) are also produced from the same tool, so the problem is even greater. However, as these operating resources often cost high 6-figure sums, it is usually not feasible to set aside replacement tools for each. This is where the risk needs to be assessed.

Situation before:

No system support available. Purely subjective problem assessment.

Situation afterwards:

The task was to assess the economic risk for the large number of operating resources as mentioned above. This means: What loss of turnover is threatened if a certain tool or device breaks down and is not available for a considerable period of time.

Plans for maintenance strategies (spare parts inventory) and replacement tool procurement should then be derived from this.

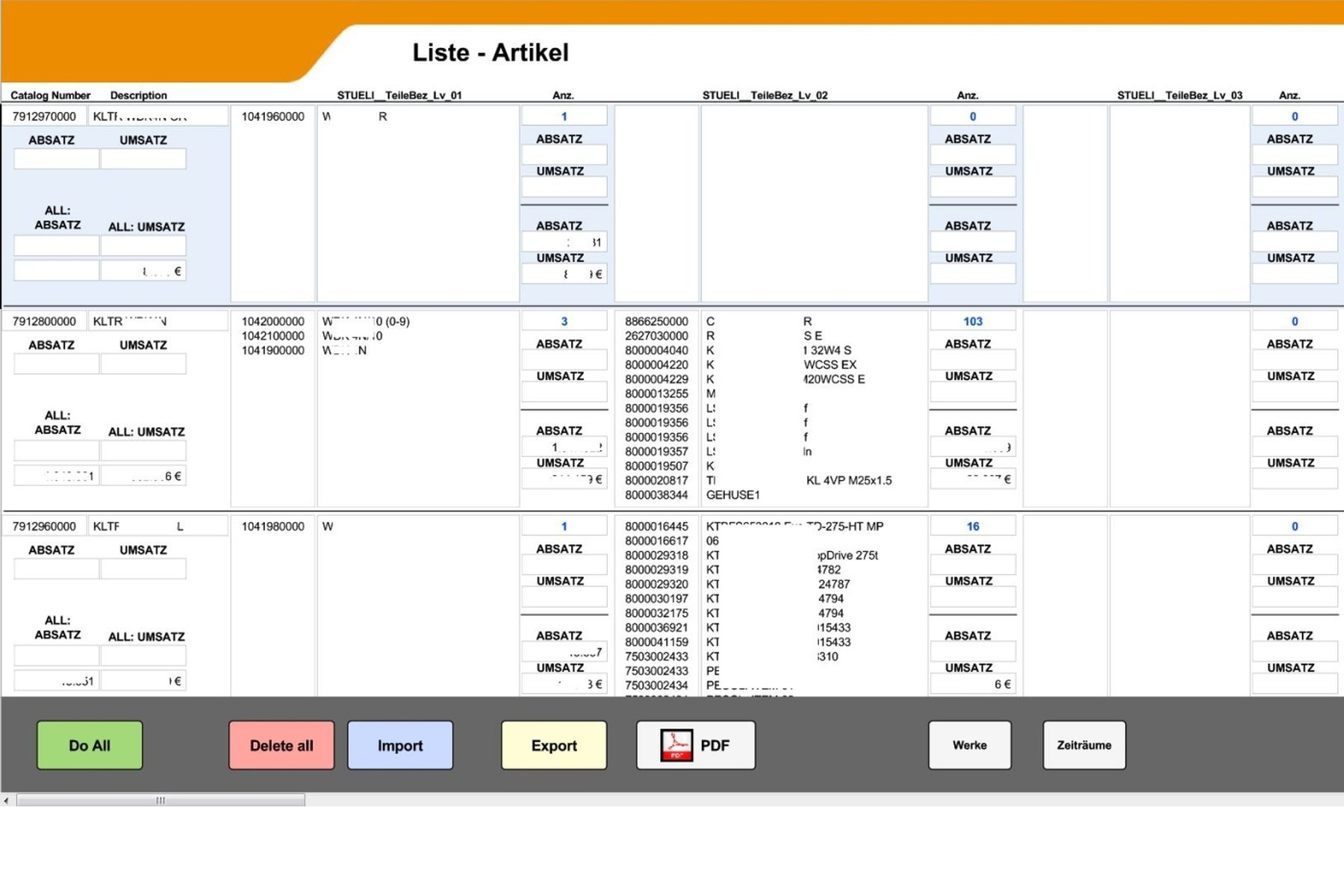

The tool: After selecting the equipment (tool) to be analyzed, the range of items produced with it was loaded according to the ERP data. The plants (operating sites) to be analyzed and up to two time periods (e.g. current year and previous year) could then defined and the dissolving process was started.

The application showed the items involved and their sales and turnover data in the respective period for each BOM level. Once the item structure had been determined, the sales and turnover totals were added up so that the total turnover associated with each individual part could be easily identified.

The sum of all data records described the loss of sales in the event of a resource failure.

Each row accumulates the sales for the products the article in the first column is contained in