Database for quality management agreements with parts list analysis

Problem definition:

Over time, customers began to required to agree quality management agreements (QMAs) with my former company. These define how to deal with changes and quality problems, also with regard to the flow of information to the customer. There were two different variants: One agreement with a defined range of articles and the other with a flexible range of articles which could be described as "all articles that we buy from you". Some of these QMAs covered 30 pages or more and were difficult for non-experts to understand. The requirements/agreements they contained were also complex and very often phrased differently.

One point that obliged us as a company to act was that every change to the geometry, production process, or production location of an article had to be agreed on with the customer in advance.

For this reason, the individual parts of these articles also had to be monitored.

Situation before:

Our internal IT-Department was unable to solve the problem.

Situation afterwards:

As the company was under pressure, I tackled the problem myself.

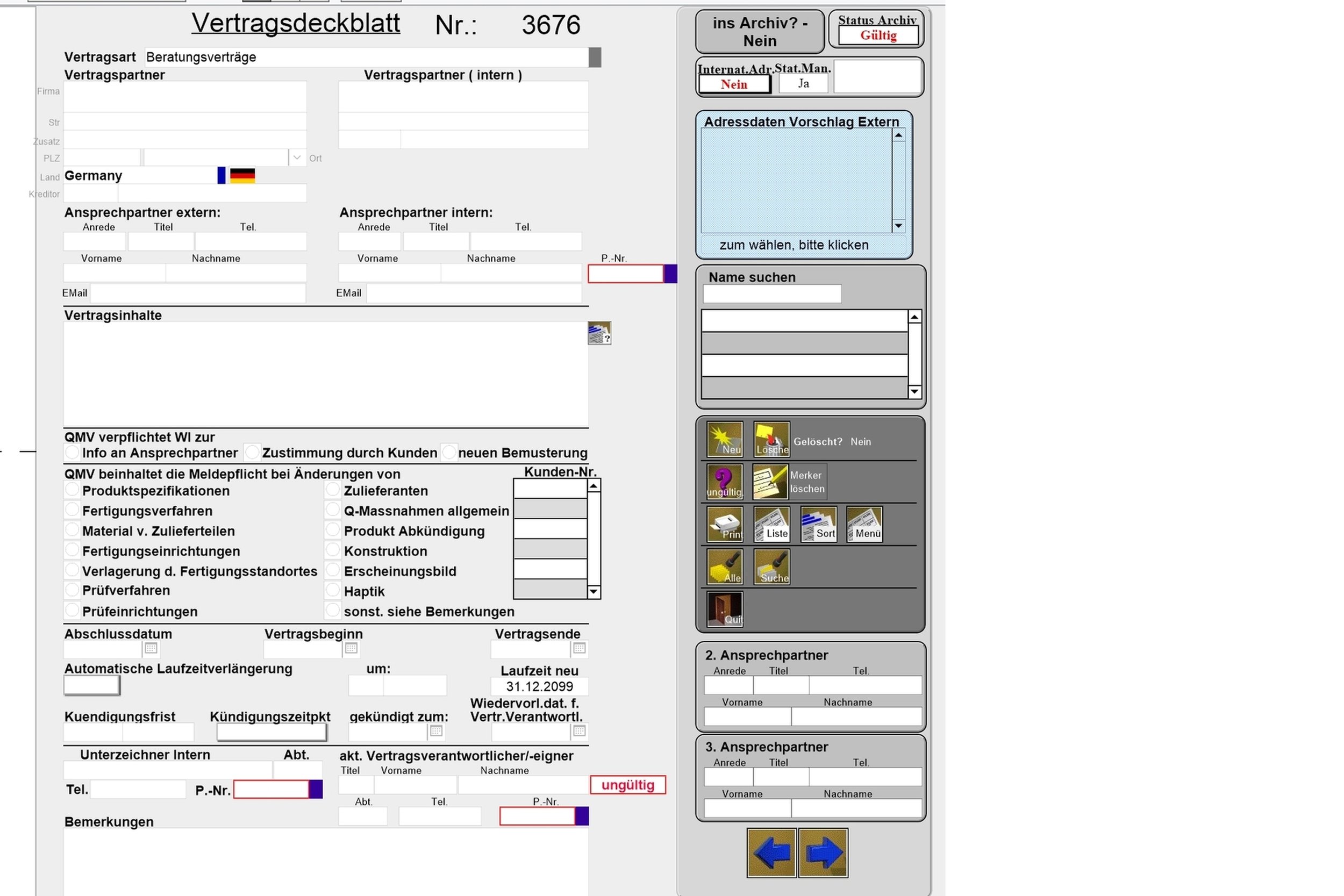

First of all, I was able to arrange for the contract texts to be studied by a knowledgeable person and their content categorized. As a result, it was possible to formulate around 20 action points that could be used to describe the effect of all QMAs. For each contract, only the points that were bindingly regulated in this document needed to be ticked. This made it clear to everyone what needed to be done in the event of a hit.

Then the contract database, in which these QMAs were also managed, had to be expanded so that a list of any length with saleable article numbers could be attached to each contract. These articles were then broken down by my system according to their parts list and the individual parts determined in this way were linked to this QMA up to the raw material. The other, flexible QMA category required information on which customer numbers it should apply to (a company could order from different customer numbers for logistical reasons). With this information (customer numbers & country), the order backlog could be searched every day to see whether this customer number had ordered an item for the first time that had not previously been linked to their QM contract. If so, this article was added and broken down into its bill of material (BOM) components.

This made it possible to meet customer requirements in the change and quality processes.

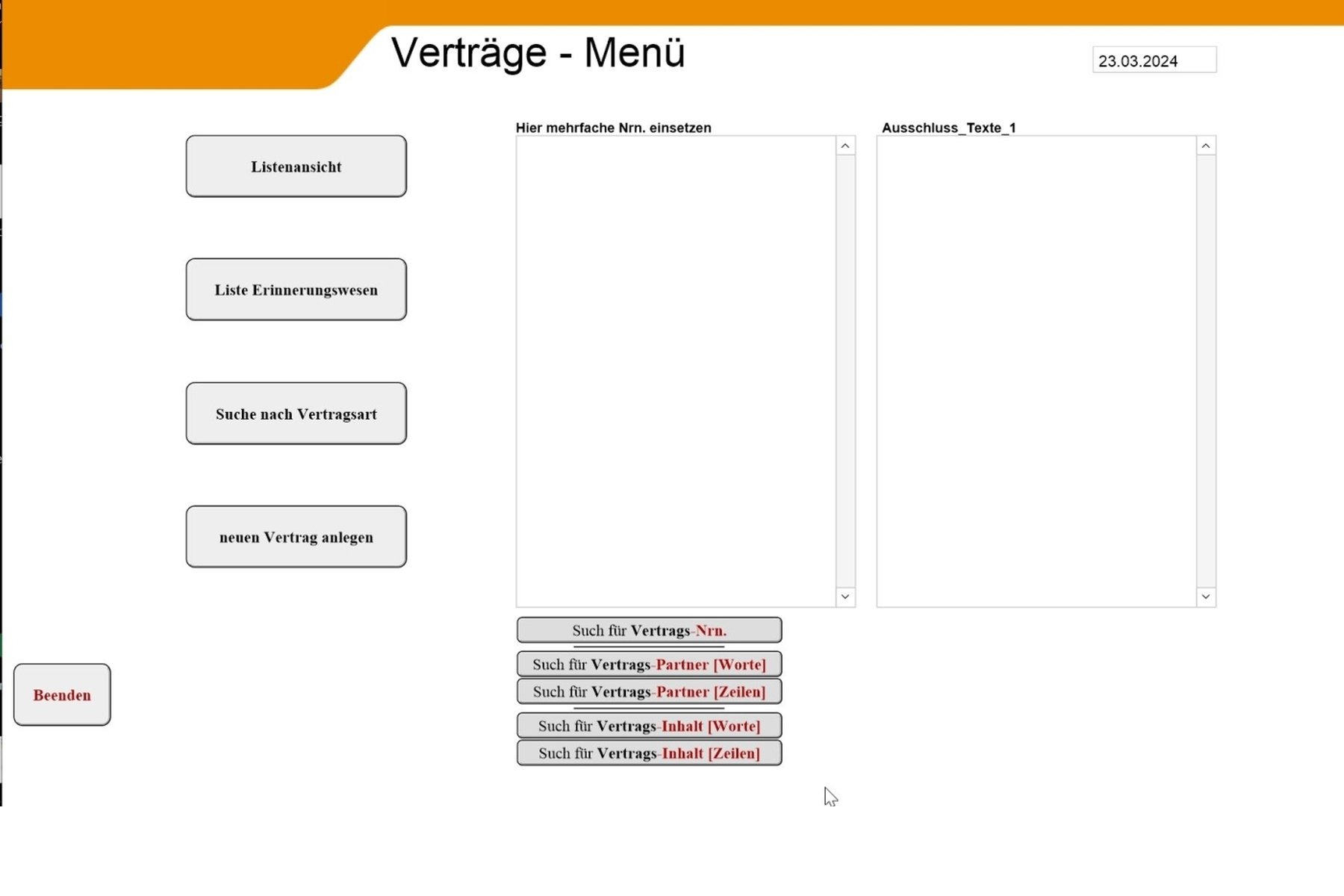

Menu with navigation and search options

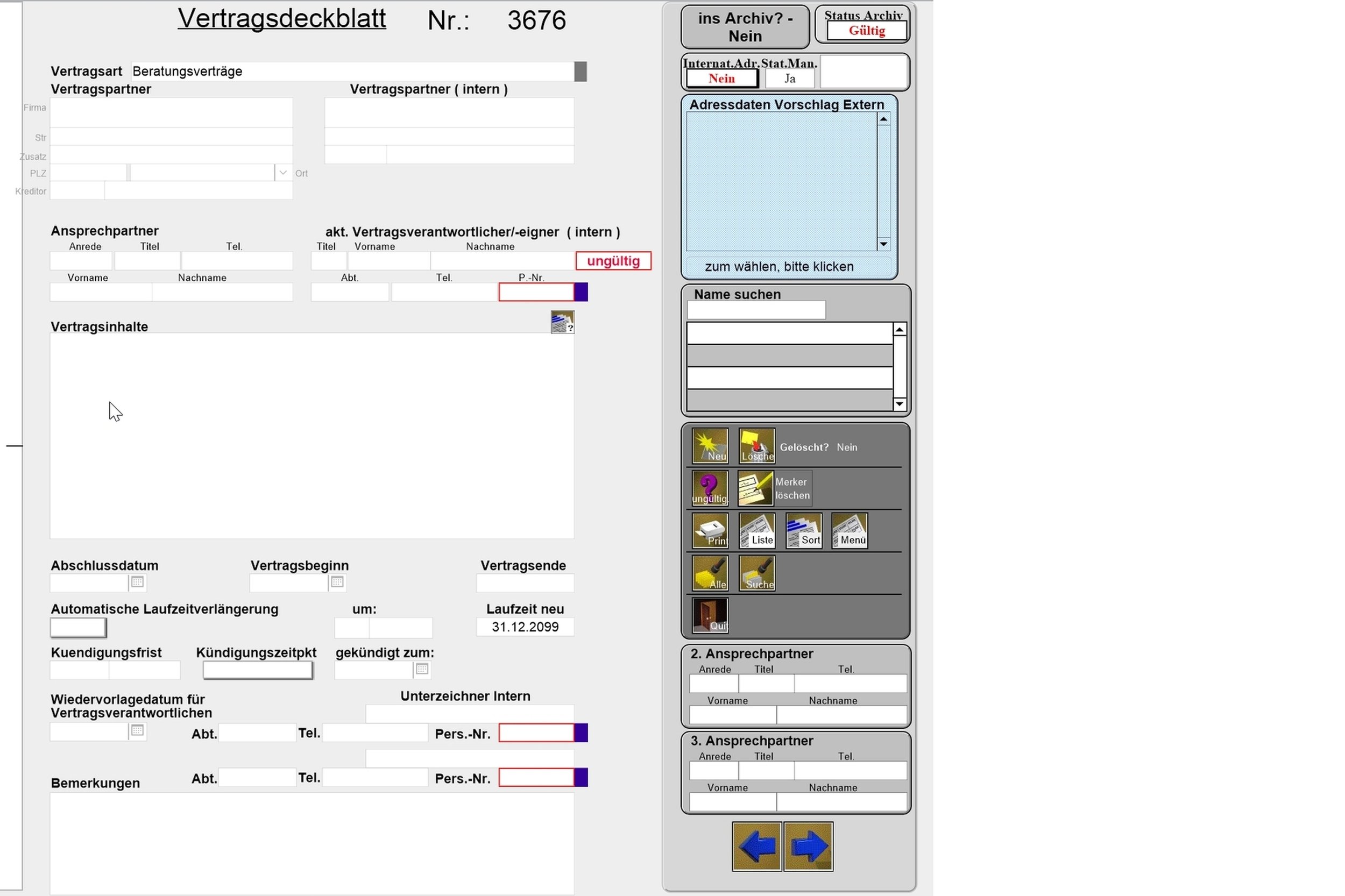

Form view standard contract

Form view Quality contract with content classification

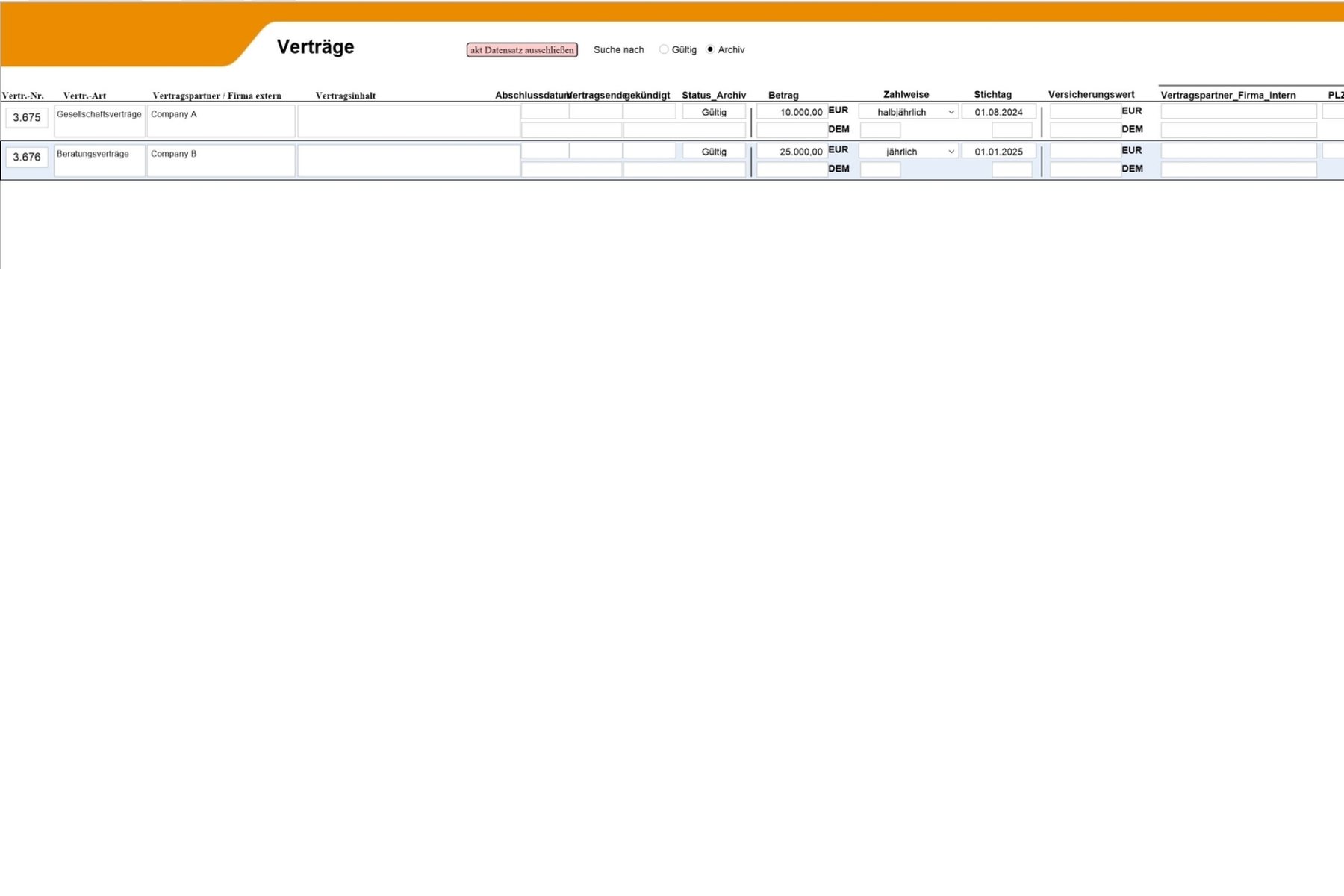

List view for overview

List of connected Customer-Nos. to monitor the open, daily order volume