Production trials & measurement sample management

Problem definition:

Extensive forms had to be filled out manually to carry out production trials due to tool- and article-changes, the testing of new materials for certain articles or special variants for customers. The respective master data had to be looked up manually in the ERP system. These production trials then had to be submitted, checked and assessed by a qualified test center. They were then cataloged and stored for several years.

All these processes were either Excel or paper-based and could not be evaluated.

Situation before:

Paper lists

Situation afterwards:

Right at the beginning of my work as a production planner, I was annoyed by the enormous amount of time it took to fill out the forms. I also happened to experience that the same attempt was initiated by different people within a week who knew nothing about the same issue. I therefore began creating the application for production tests with plastic and metal tools. This was in the mid-90s and the application was active without interruption until I left Germany in October 2019.

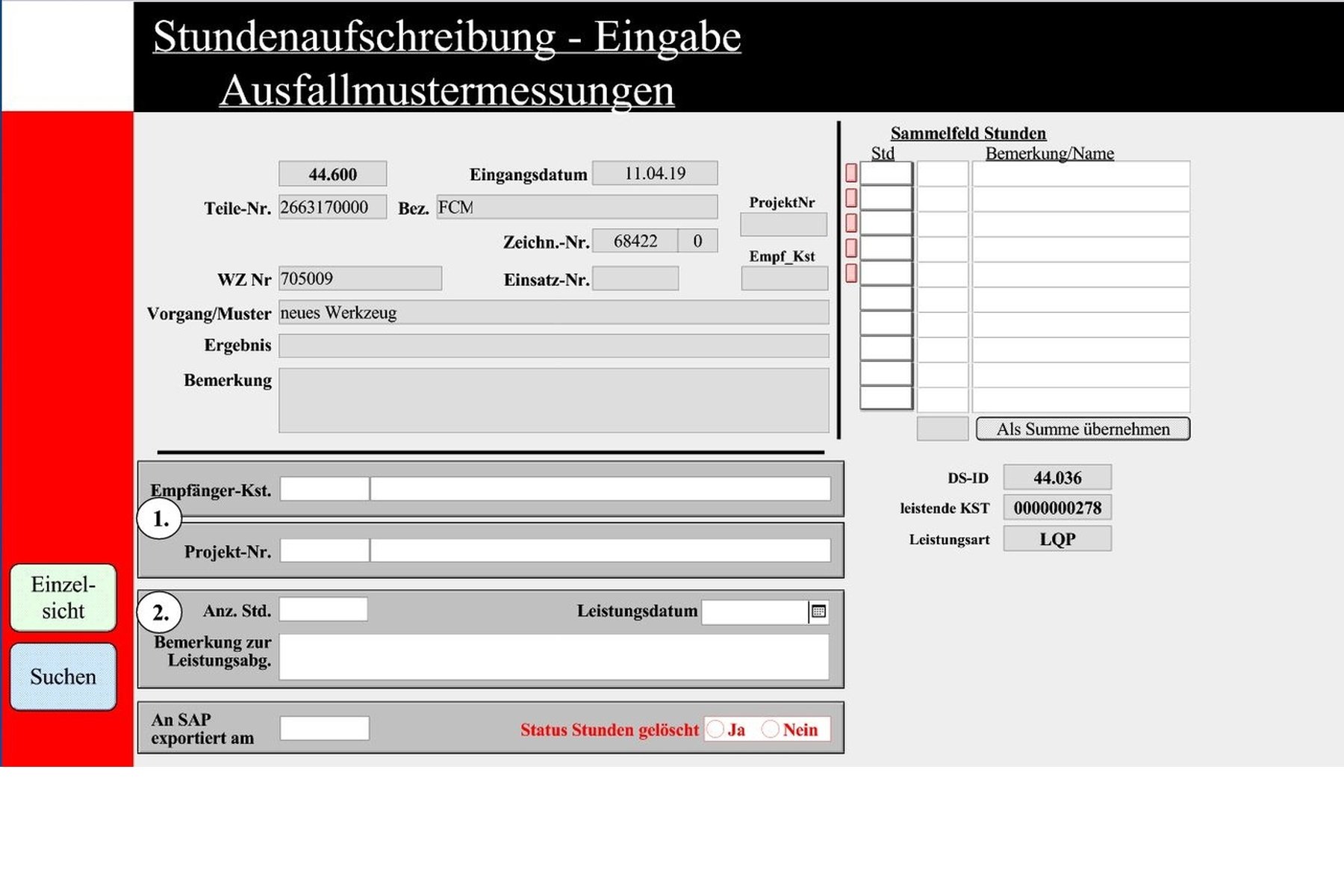

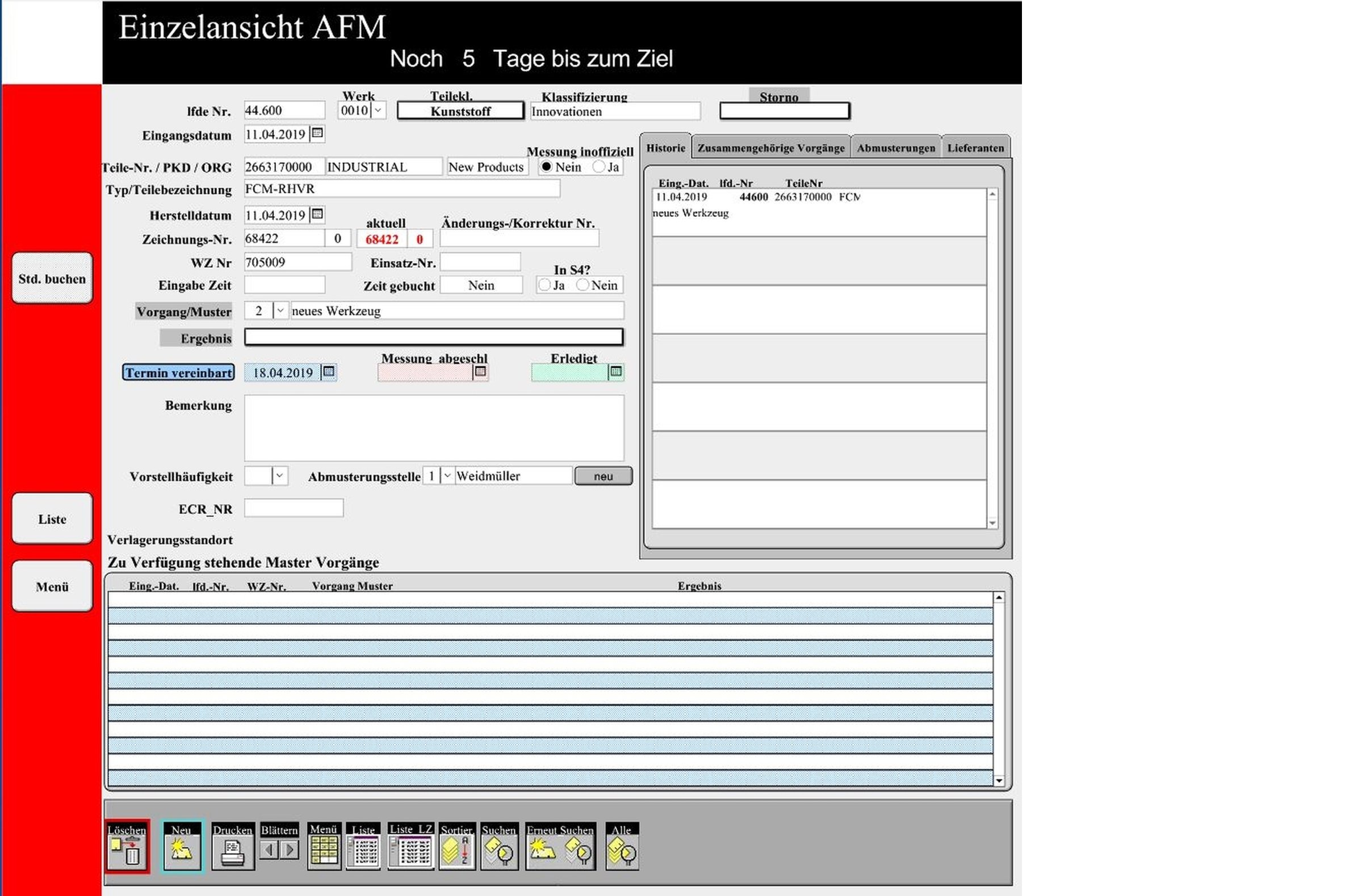

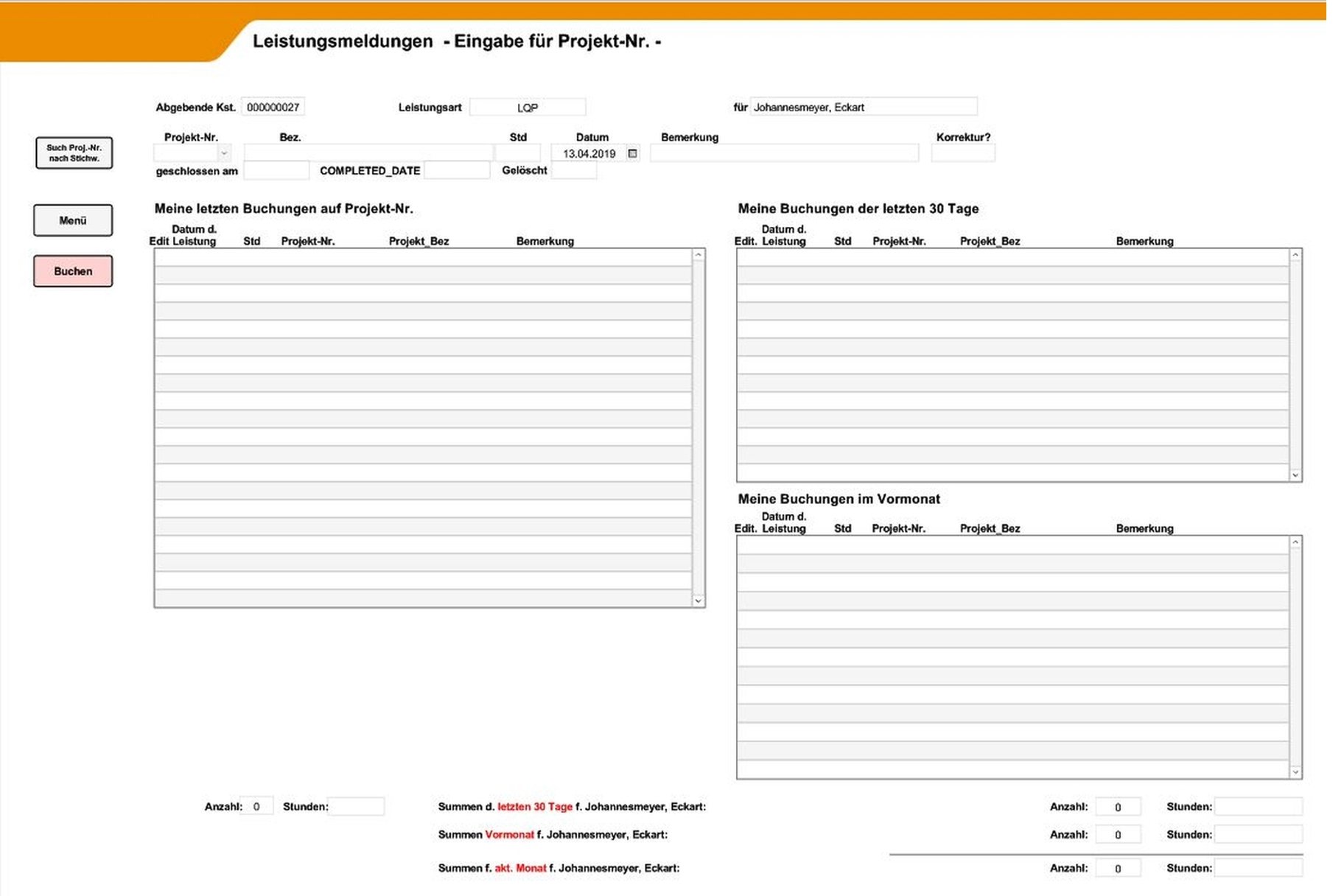

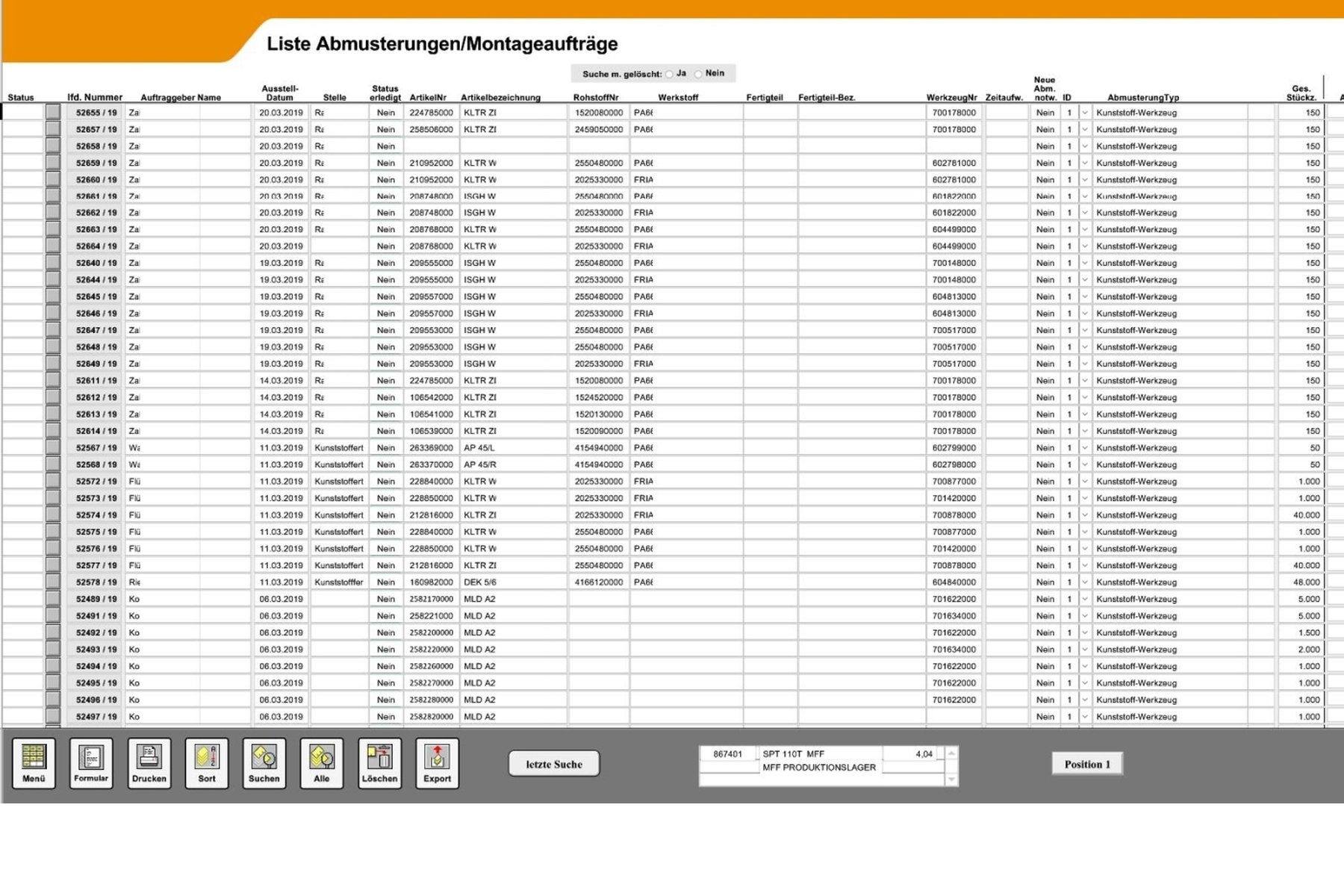

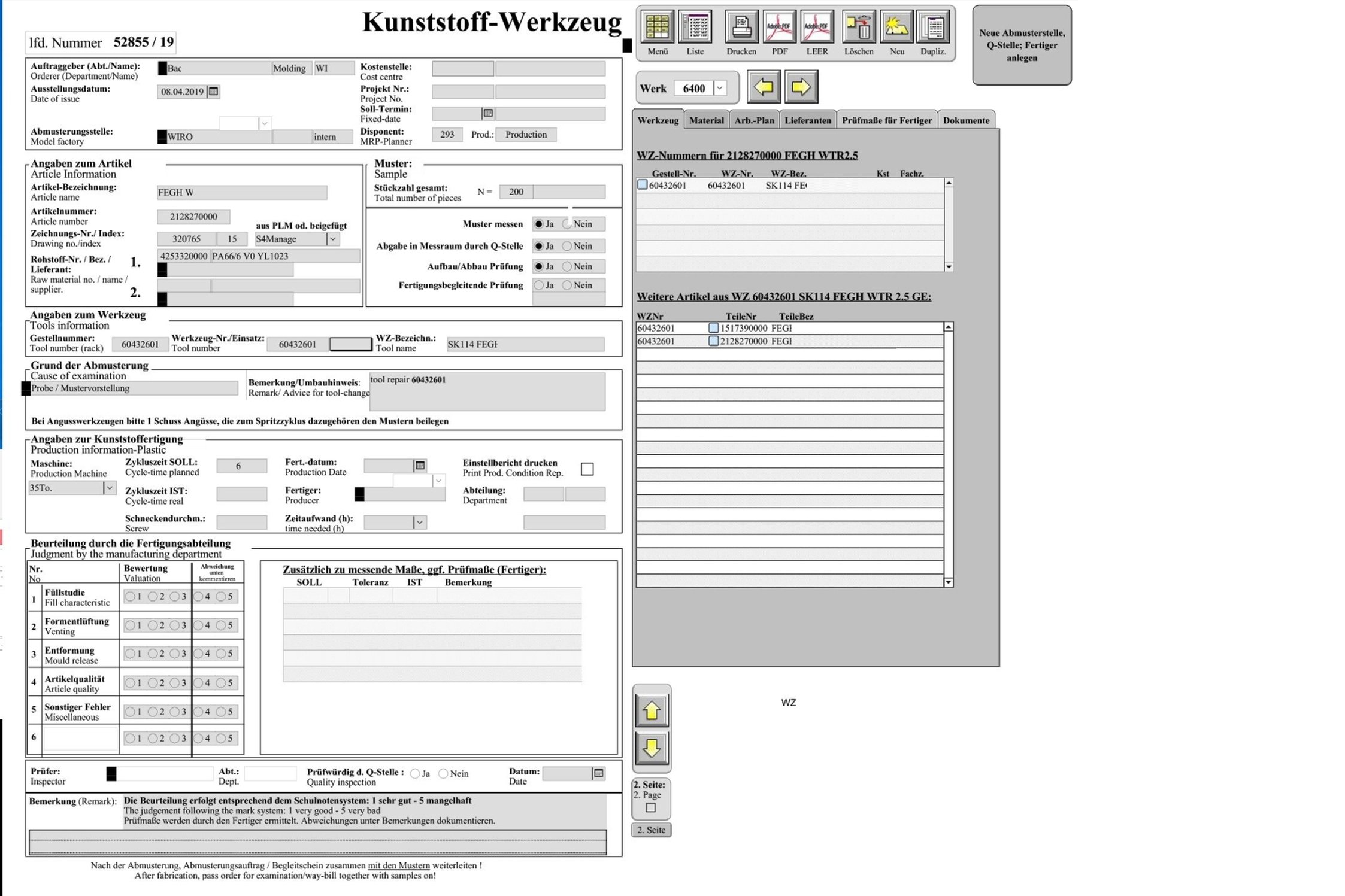

By entering the reference article number, the system was able to fill in many data fields automatically. It also offered the planner a list of existing tools that could produce this article. The required machine type was then also determined with the mold. It was also possible to select plastic materials from a prefilled list.

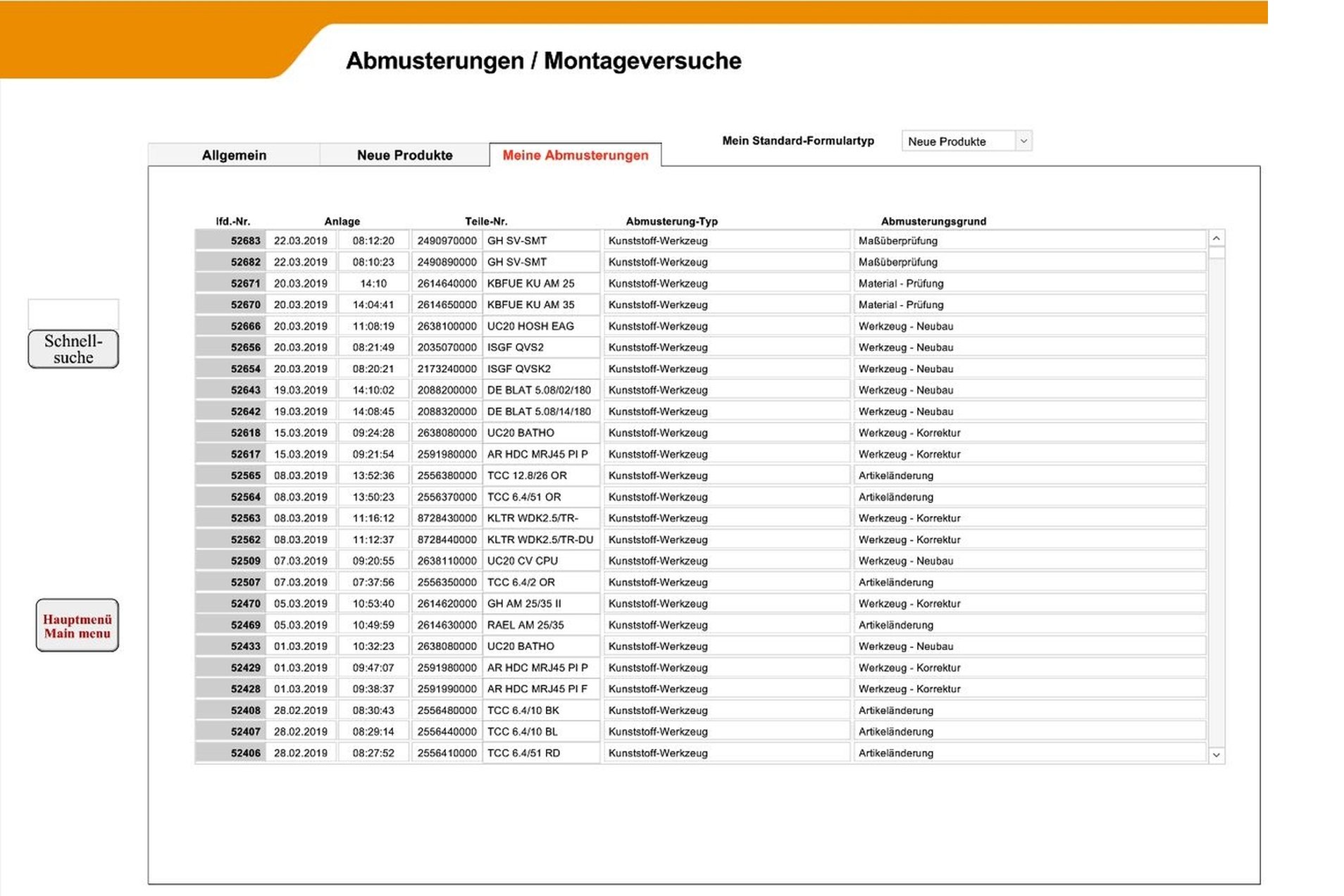

After entering the complete data for this production test, the system was able to show the corresponding hits from the past so that a duplicate test could be avoided if necessary.

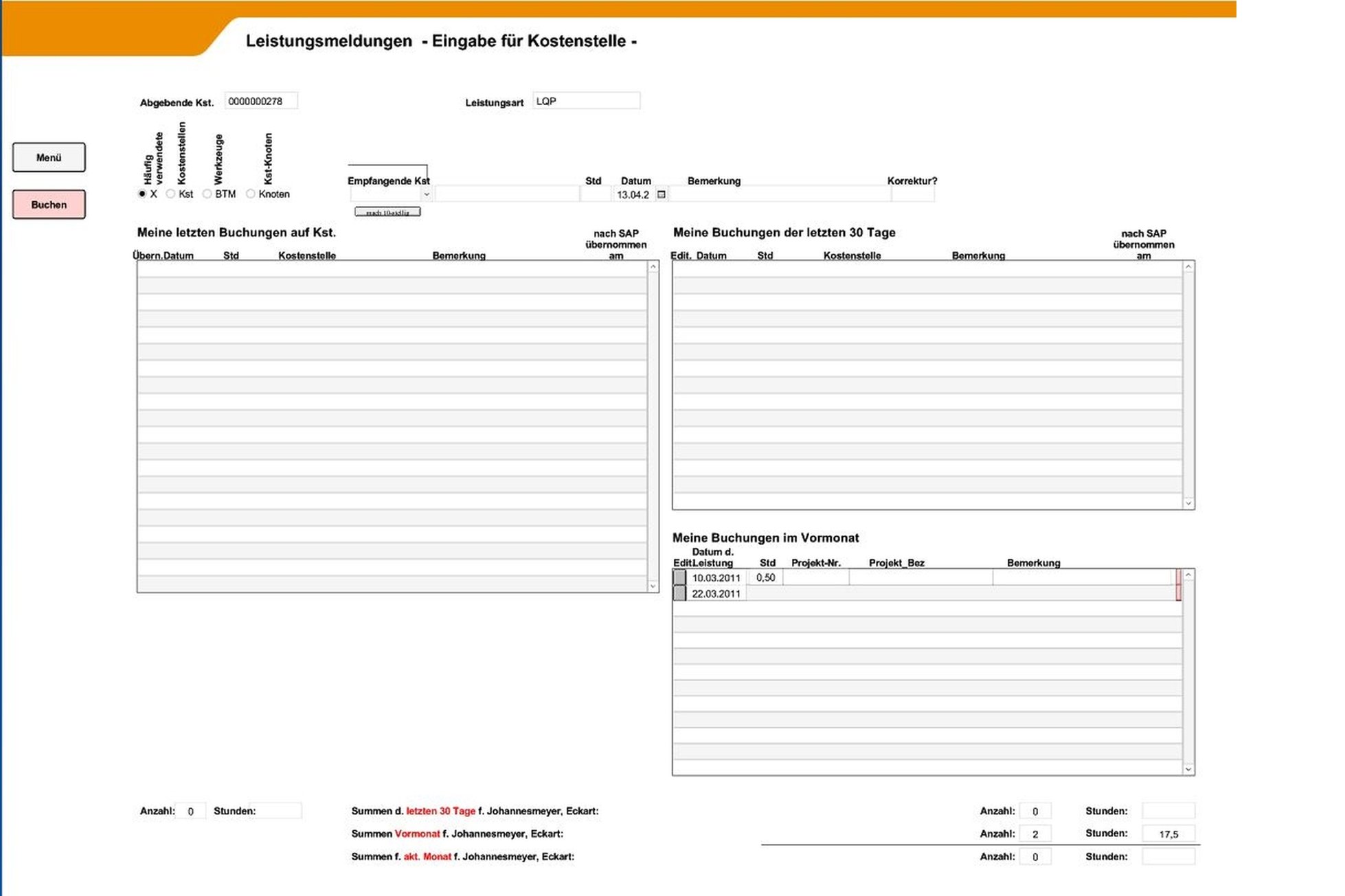

As the process was now in the system with its own ID, the results of production with regard to manufacturing behavior could also be documented. The sample testing center also had a sample management database developed by me and was able to document its results in it. By recording the production test ID the results of the measuring room for the production test could also be displayed in this application. By evaluating the sample database, the development and toolmaking departments could also be given feedback in the form of a key figure on how many maturing cycles they needed in each case.

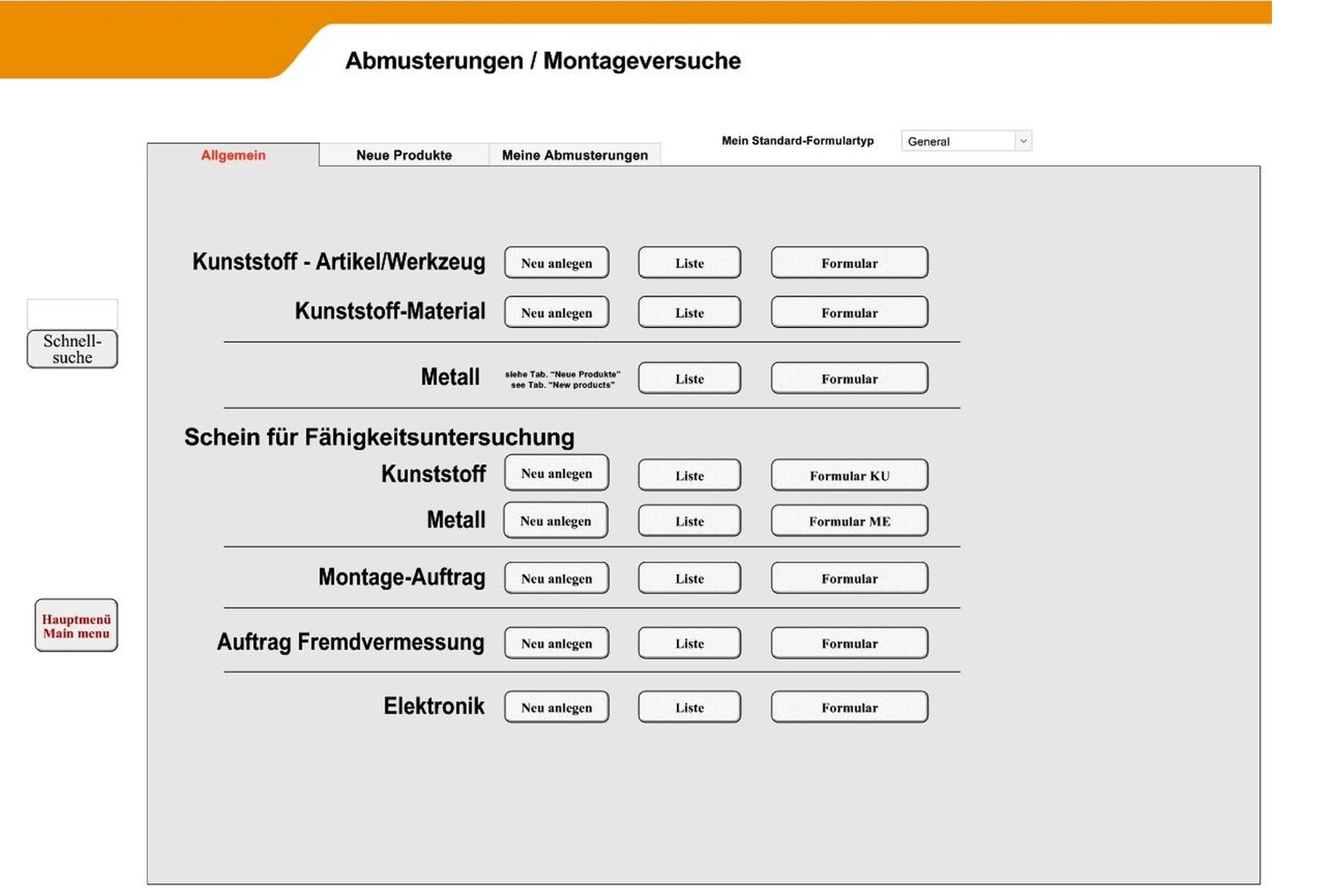

Very soon, the application was extended to create samples for plastic/metal tools and materials, capability studies, assembly orders, external measurement orders and electronics. In addition, this application made it possible to use the same procedure in different plants.

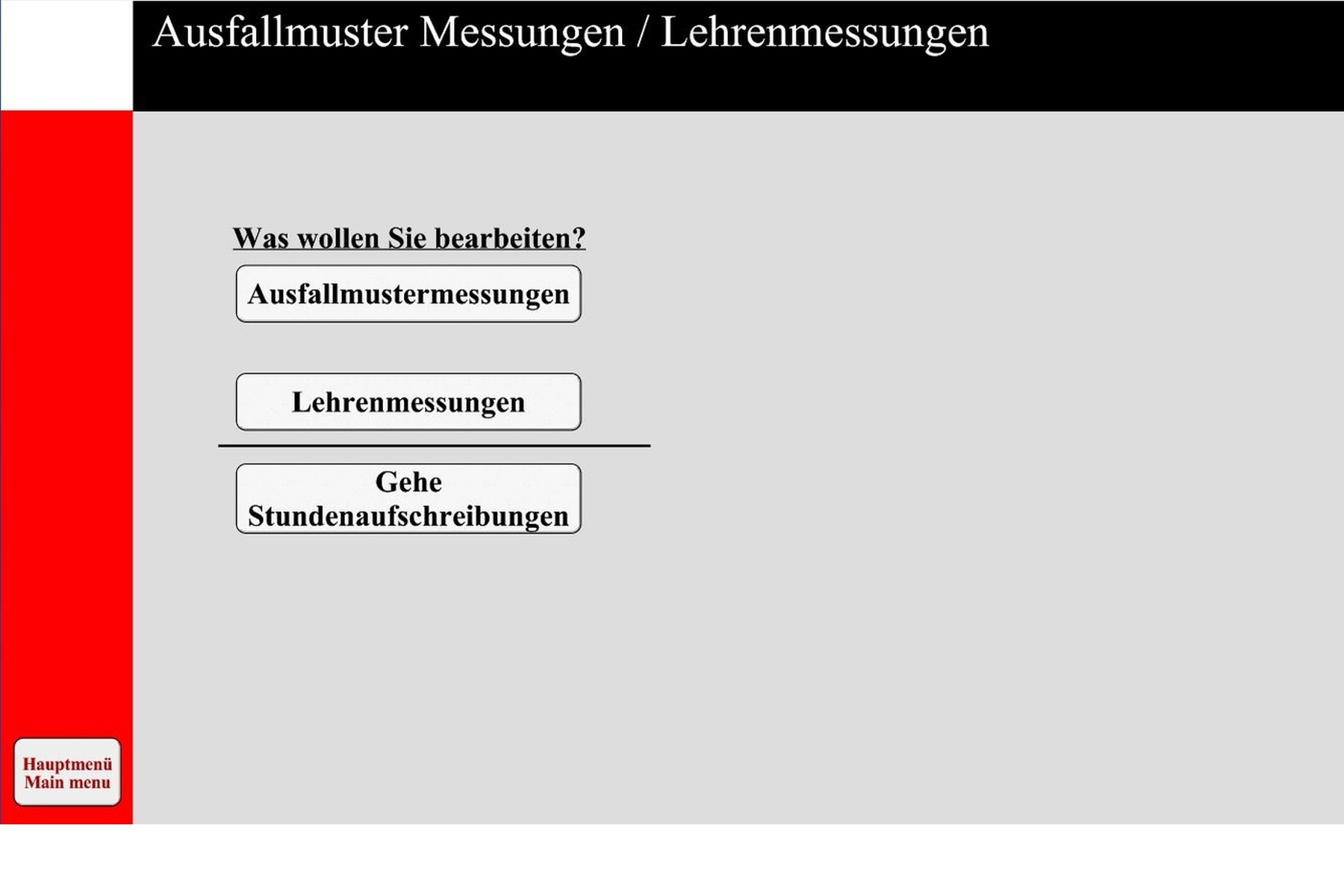

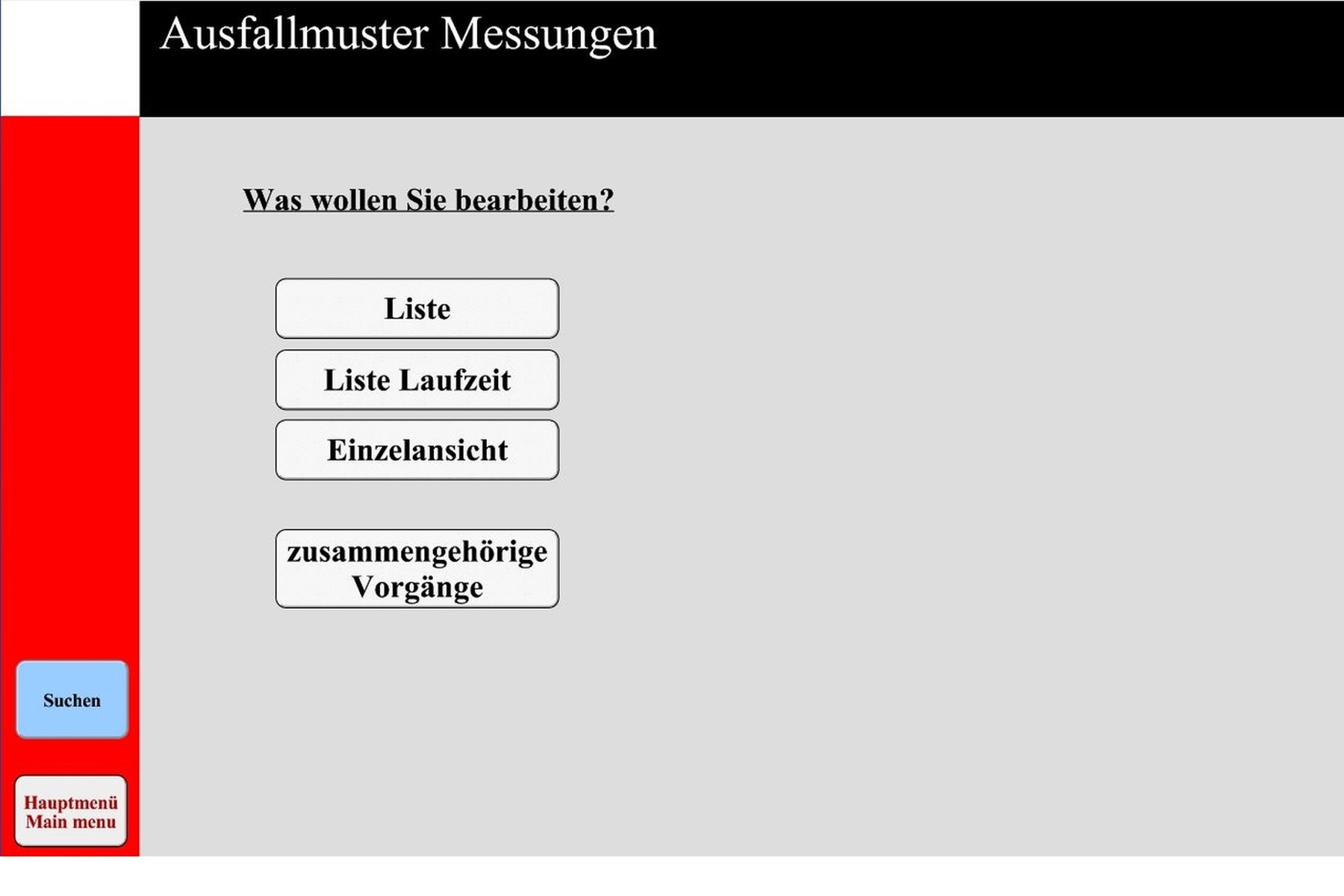

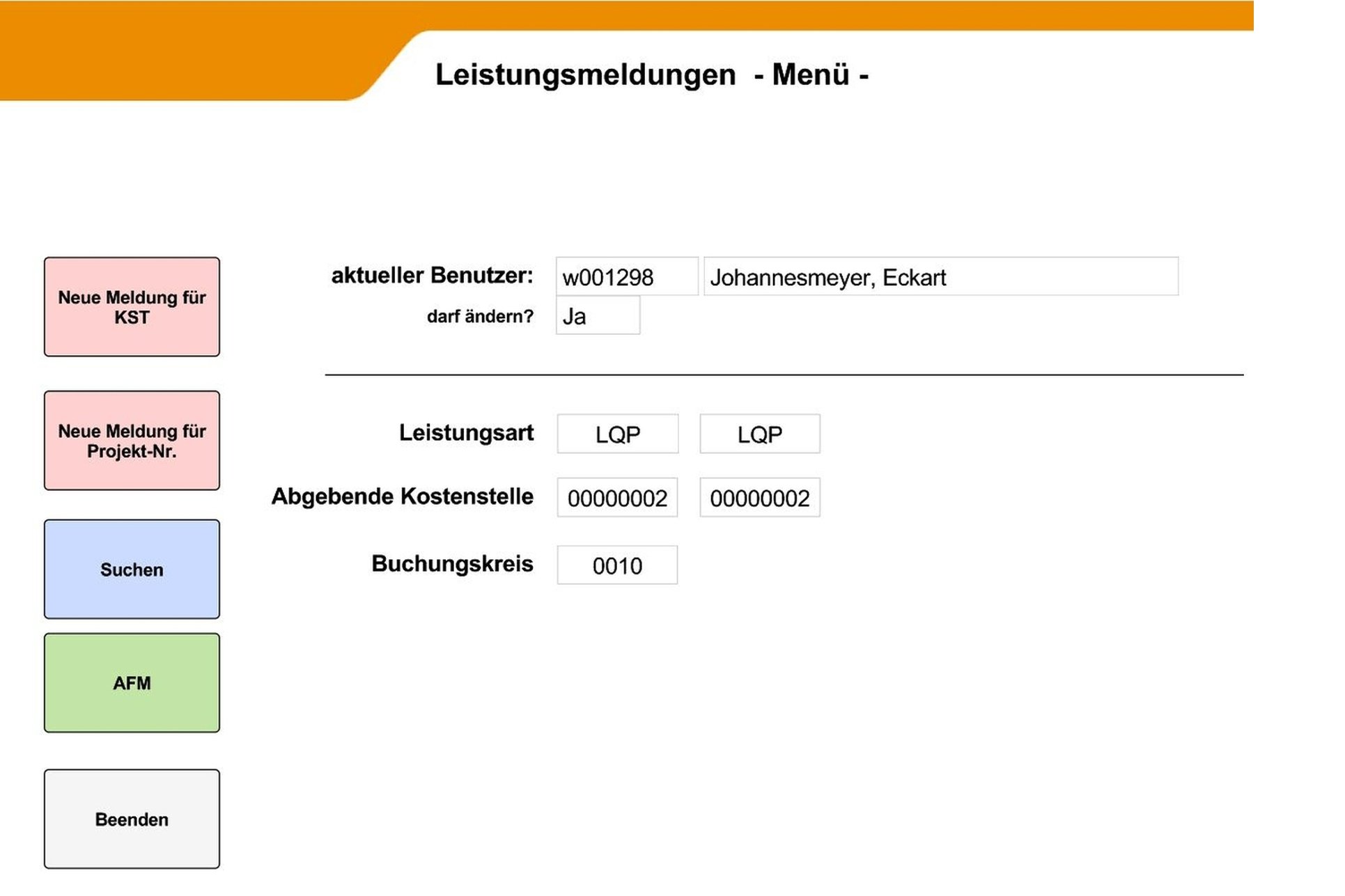

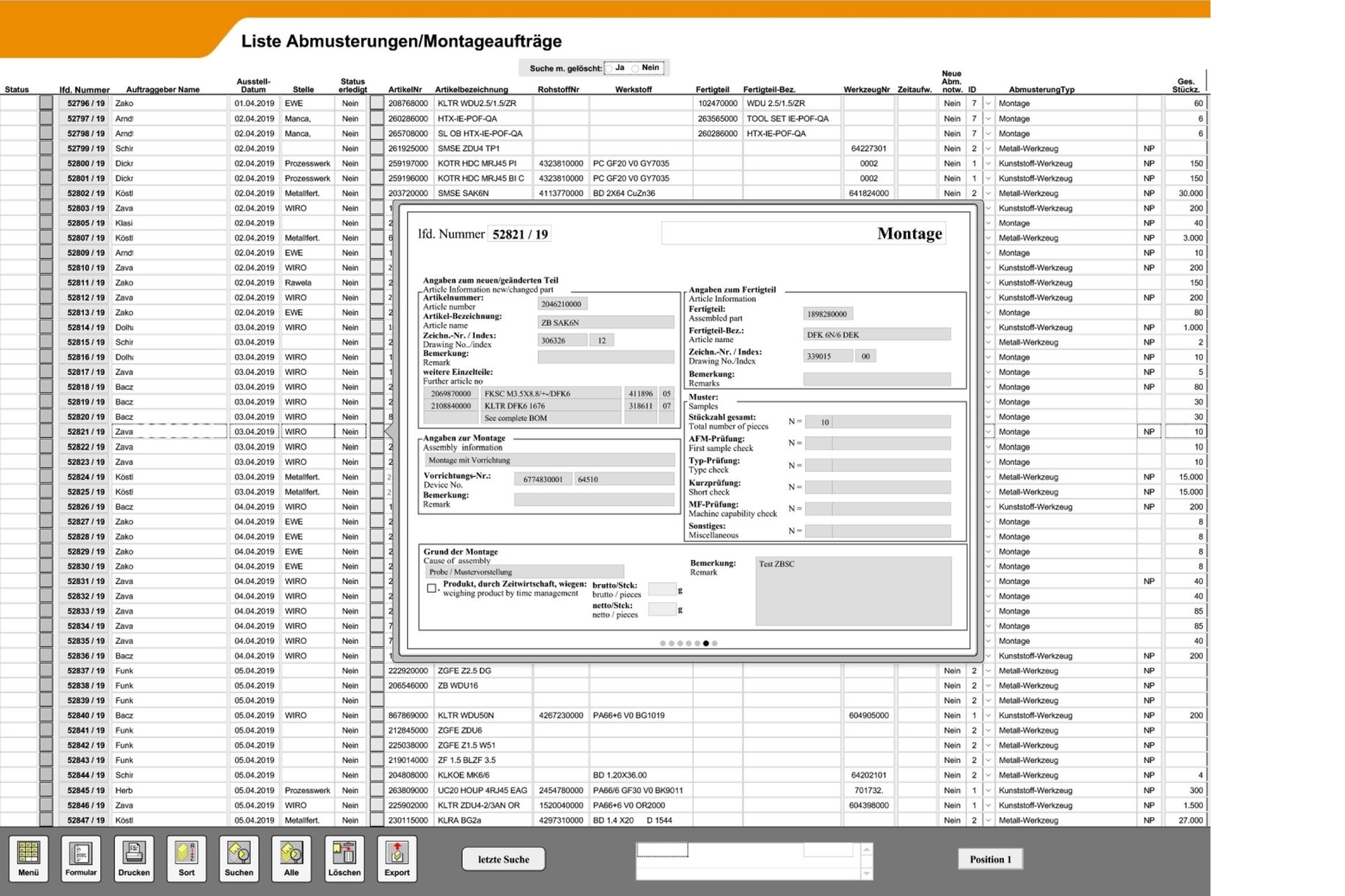

Menu

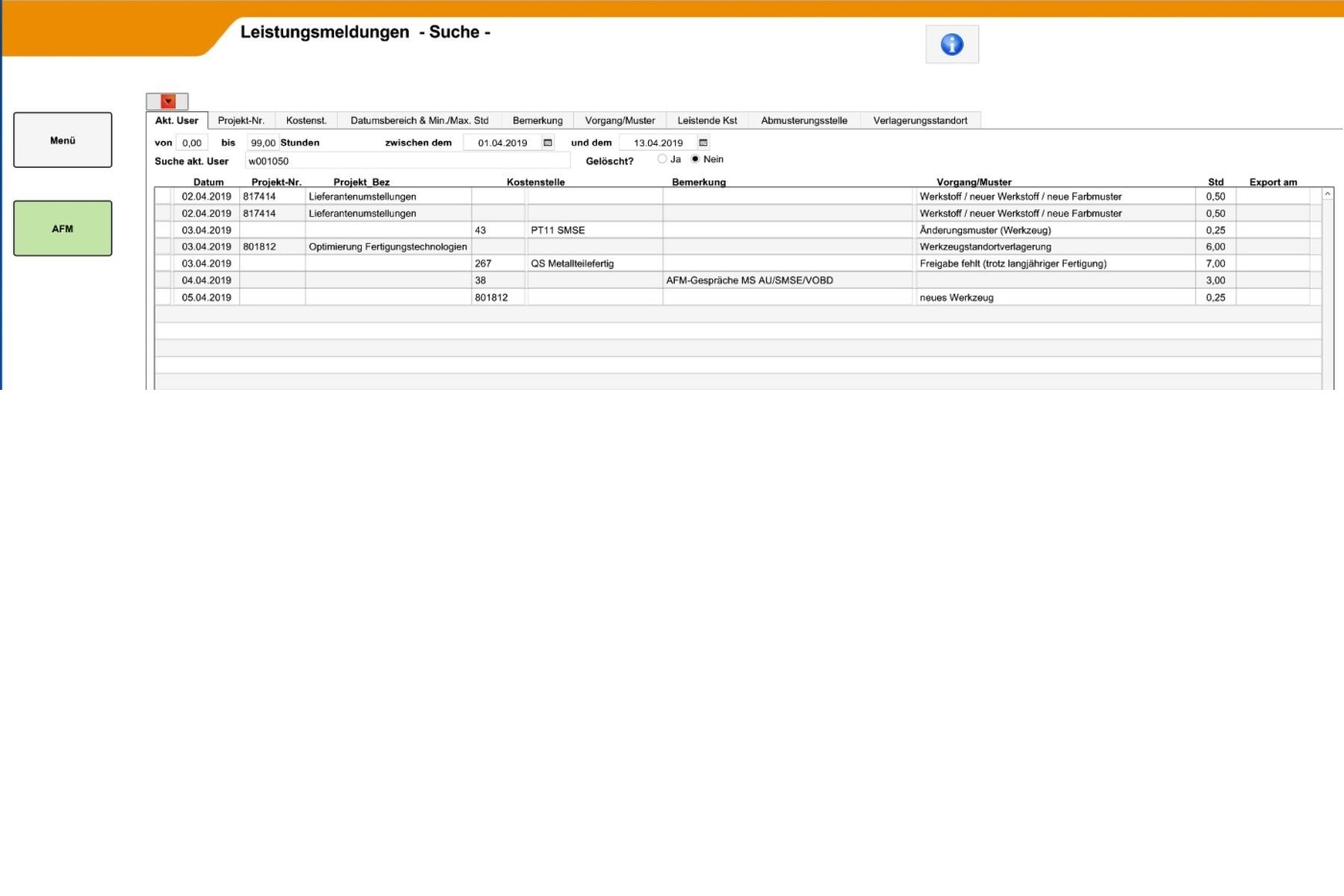

View shows all subjects entered by actual user

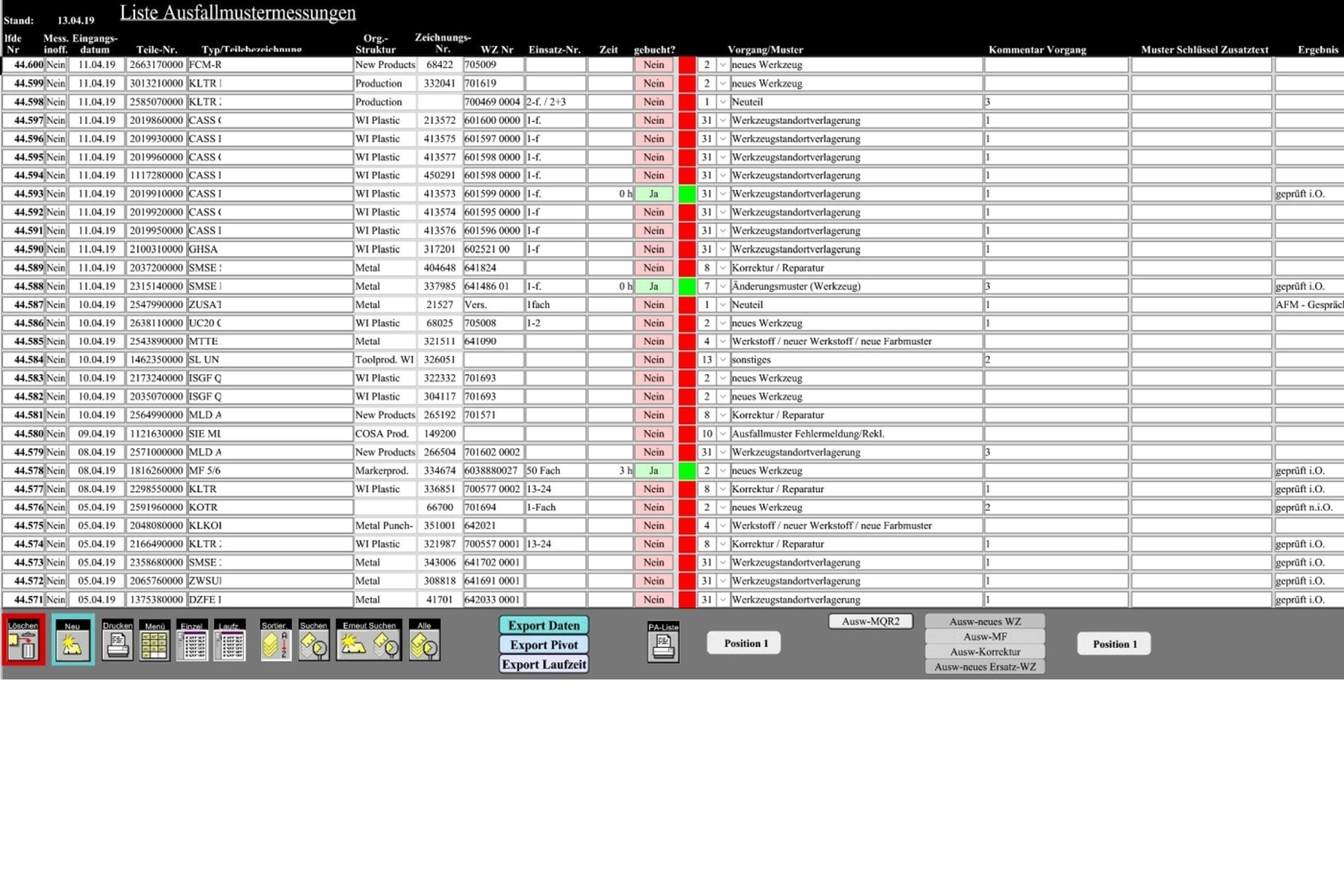

List to search and for overview

Preview function to find certain subjects faster

Form for an injection molding tool In the grey area to the right: Related articles are shown Materials and machinery can be searched and selected